Need to attach shelves to your concrete floors, floating stair runners to walls, or lightweight fixtures like mains boxes and wood ornaments? Consider using masonry anchors. There are dozens of masonry anchors out there, and each will be better suited for your application. Some are heavy-duty and permanent fixtures like expansion sleeve and wedge anchors, while others are temporary and generally good for light tasks like nylon anchors used in attaching handles, brackets, electrical saddles or anything under 20 kilos and needs to be removed later on.

For medium tasks and attaching fixtures with some heft, one of the best solutions are masonry screw bolts. These work in concrete, concrete block, brick or mortar. These cheap-to-buy and easy-to-install anchors have high holding strength, and yet can be removed if you change your mind.

What are Masonry Screw Anchors?

First, let’s get all the names out of the way to avoid confusion. A masonry screw bolt is also called a concrete screw, concrete bolt, concrete screw anchor or branded as a Tapcon screw. This is a fastener used in fixturing light to medium loads in concrete, but also works well in other materials like wood, brick and gypsum boards. Concrete screws may resemble ordinary screws, but have significantly higher holding strengths owing to the unique thread design that burrows its way into the base materials. Different designs and sizes are available, depending on your application, the size and weight of the fixture, and the type of masonry or materials you’re anchoring into. Besides this, they’re more convenient than other anchoring solutions in terms of placement, particularly near edges.

Where They are Used

Masonry screw anchors are worthy in any type of masonry, but they’re best in concrete. They can be used in both solid and hollow-core concrete, concrete blocks and cracked or uncracked concrete with similar results. As mentioned, they’re more suitable than expansion anchors in that they take into account changes in concrete over time, like structural morphing due to temperature extremes, fatigue levels and different weight loadings and won’t cause further deterioration or cracking. In terms of spacing, a concrete screw is also better in close-edge anchoring for the same reasons.

Typical uses include fixturing ventilation systems, electrical installations fastening metal or wood handles, brackets and rails, as supports for fences and clamps, in attaching heavier steel structures and more. They e versatility is only beaten by the low price compared to other anchors and how easy they are to install.

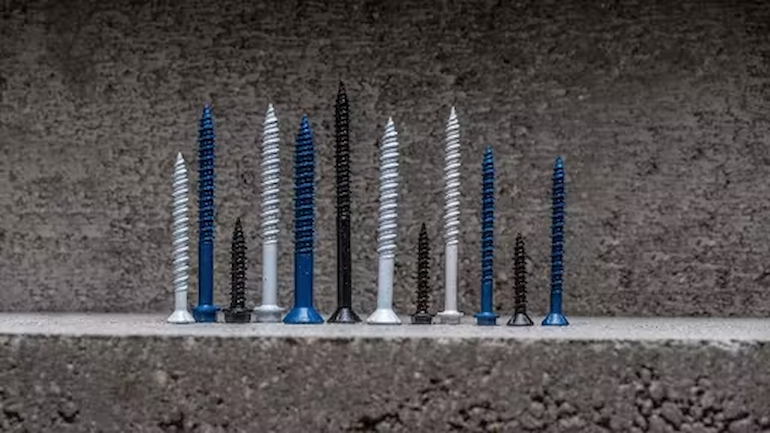

Types of Masonry Screw Bolts

The types of screw bolts used specifically for masonry are down to differing designs. This lends them additional qualities, like higher holding strength and better-looking finishes.

- Hex Head Masonry Screw Bolts – These are the most commonly used, simply because of the superior strength and the clean look after installation. The hex head has an integrated washer and the design allows for easier driving and tightening. Thread designs, either along the whole length of the bolt or partial, determine holding consistency and fully threaded bolts are often used where fixtures are heavier.

- Pan or Flat Head Screws – Flush finishes are easier with screws in a pan or flat head design. The flat head though limits the strength

- Screw with Connecting Thread- This allows for direct installation of the fixture, especially in overhead applications, like ceilings and roofs.

- Screw Bolts with Internal Thread – When you need a good alternative to drop-in anchors, concrete screws with female internal threads and hex drive heads are great for pipe routing, channel fixing, ventilation ducts and other uses. They also go by the name of rod hangers.

- Screw Bolts with External Thread – Simple and quick overhead tasks are also done with screw bolts with external threading in lighter applications. Similar usage is with self-tapping eye-bolt screws, especially in cabling and light fixtures.

What to Consider for Your Application?

Any anchor needs to be sourced in the right size for the job. A masonry screw bolt will be specified by the diameter of the thread and overall length. Units can be metric or customary. When buying you’ll want a screw bolt that’s the right fit for the pre-drilled hole. For heavier fixtures, consider using bigger hex head screw bolts.

Materials also matter, and all concrete screws are made of high-tensile stainless steel capable of permanently holding particularly heavy and large fixtures. If used outside, source bolts that include galvanised or zinc-plated finishes to avoid corrosion.

Benefits of Masonry Screw Bolts

Let’s start with the obvious. Installation times are considerably shorter and all you need is basic tools – rotary hammer drills for drilling into the masonry and impact drivers for tightening the screws to the correct torque. Adaptive installation kits eliminate the need for multiple tools, meaning everything is done faster.

Not expanding into the masonry, means structural integrity is sustained for various base materials and surfaces, and also allows for closer placement along edges. Tensile strength is comparable to heavy-duty anchors, paired with high resistance to environmental factors like water, high heat and corrosion. Screws are available in differing designs and sizes for a variety of applications, and come in cheaper than anchors in comparable length and width and holding power.

All types are readily available in most hardware stores, but for the largest range look to stores specialising in building and construction tools and materials.